Systems and Structures to Avoid the Sound of Deadlines Whooshing By

Adopt the SMART rules of PCB Data Management and avoid additional cost and/or lost design time.

When we begin to look in more detail at how to do anything, it becomes a little problematic. The reason is that every organization varies in product, structure and management requirements. We can guarantee that there will not be a “single” answer or solution to the questions at hand. My intention therefore is not to prescribe a sole structure or solution for accomplishing design success, but rather to provide a detailed explanation that will give an example of how it can be done. Then to allow you to modify and adjust it as required. My aim is to give the bird’s eye view of this whole PCB Data Management thing, with the hope to point you in the right direction. As a school teacher used to tell me… “your mileage may vary”.

I experienced this first-hand recently, when I was organizing a PCB Data Management system for an international company. There happened to be several areas that were NOT planned out and wouldn’t you know it, the harsh rule of the universe hit us right between the eyes, resulting in us painting ourselves into the proverbial corner, and needing to restart several times with that world famous “Plan B”.

The Five Pillars of all PCB Data Management Systems

There are several key principles that are NOT optional. Not having these principles in place will substantially increase the possibility of failure, which we know by now, translates for us as PCB Designers into additional cost and lost design time, and several other very nasty possibilities. To help us remember these principles, I will use the acronym S.M.A.R.T.

Understand in the beginning, that these five pillars are not particularly tangible or physical items but would rather be described as ideologies. Just as a pillar in a building has the main function of providing support and structure, these pillars will provide the support and structure same for our entire PCB Data Management System.

Each one of these pillars are required. To pull one out results in the toppling of the others.

The Five Pillars of PCB Data Management

S. - Singularity

M. - Managed

A. - Architecture

R. - Review

T. - Tailored

S- Singularity

Singularity of what? Singularity of Data and Processes. When working with a team who are functioning from different data and following different procedures, it doesn’t take a psychic to determine the results. There is absolutely no way to control the quality or outcomes. Can multiple people starting at different locations, going in all different directions, with all different maps, end up at the same location? Nope!

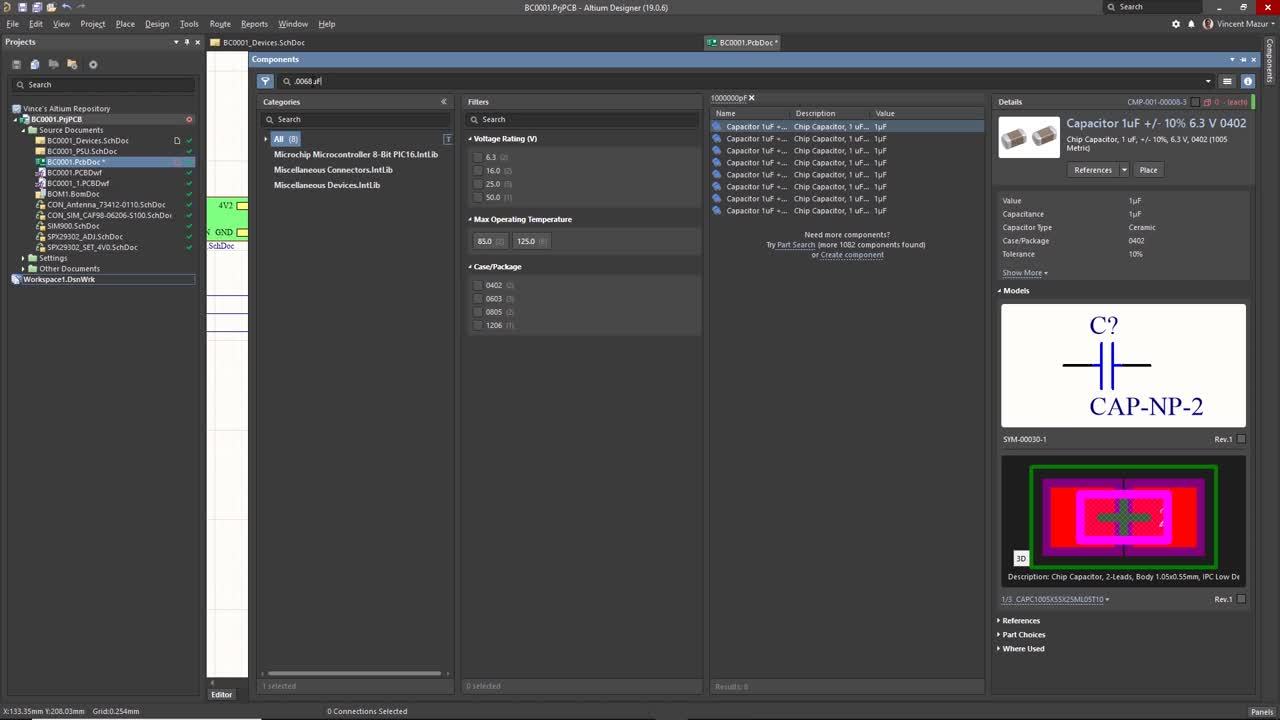

I have seen, more times than I wish to count, the problems caused by what is called “Rogue Libraries”. Rogue libraries are component libraries that are not controlled or verified. Consider the massive amounts of work required to prepare a PCB design. The engineering, layout, fabrication process... and then as you get into assembly the notorious unwanted phone calls begin, apprising you that the manufacturer is hitting “snags”. Problems such as parts not going onto the PCB because of wrong footprints, or other components tombstoning or falling off. Then you start to investigate the problem, only to find that someone’s personal “Rogue Library” was used resulting in the entire fabrication being scrapped. At this point, you begin that long walk to the manager’s office to explain the situation. Not a good feeling.

Several years back, I joined a company where, although they had existed for many years successfully, the PCB design area had absolutely no structure or organization. It would be an understatement to say it was in total disarray. It was evident from how many spins of board designs were being done. I remember going over to one of the designers, where he opened a desk drawer filled with Bare PCB boards. Letting me know that those were the designs that did NOT make it through Assembly due to some problem on the design. It was like being kicked in the gut by a mule. When I investigated further, I determined that we had a total of around 1123 PCB libraries in use. All different kinds and sizes of course. Multiple footprints with the same name. Every designer with their personal library. No wonder there were problems!

Our hope in every design can be summed up in a single word… Integrity. What is meant by that word? It is defined as “the state of being whole and undivided”. That is a great mental picture of a PCB Design. To be unbroken and undivided. I like that. When we were working from a thousand libraries, we were starting from a thousand possible different places and with those, a thousand possible problems. Even worse, we were not starting from what would be considered strong and verified (ie. proven) data for any design.

There is an old saying: “To get something you have never had, you need to do something you have never done”. I knew the solution to fix the problem, although it was a radical step. My solution was simple. On a Friday evening after everyone had gone home, I went onto the server and DELETED ALL THE LIBRARIES. I must say that was an interesting Monday morning. As I said, it was radical but necessary. In a short period of time after that, we began to see great improvements in the PCB designs. It began with getting control of the source of information and making it singular in nature. The moral of the story is; to have integrity in PCB Designs, we have to first have integrity in our information and processes.

M- Managed

The second pillar giving us the required support and structure is Managed. This may sound like a novice idea. It cannot be assumed because you’re operating from a single source of information that it is managed or controlled. Controlled by several characteristics at a minimum; management controls the following:

Roles

A large variety of information is needed at various stages of the design process, by various people in that process. Each of those individuals has various roles and inputs in the design process. A good PCB Data Management System first controls who has access. The best systems can be set up with a very strong hierarchy and user-definable levels of access control. This allows a tailored approach based on divisions, team structures, capabilities and trust & authority levels.

Permissions

Permissions are closely coupled to the hierarchy of roles. If the roles determine who can have access to data, then permissions answer the question of what they can do.

For example: some will only have the need to view specific information. Others might need to use that information in some way, yet others might be required to verify or be required to edit information. With these roles & permission levels, it keeps things managed and in control. There is a belief in some companies that it is better to allow everyone the access to edit information such as items in the component library. That may not be the best practice; having that permission fall on a trusted few is usually a better approach. By doing it that way, we can easily manage data quality and integrity.

Revision scheme

Each PCB Data Management System must have some type of revision system. This will vary from company to company. A very popular system is a Numeric-Alpha system. For example: 1.A. The Number is changed with major revisions and the letter is changed with minor revisions. It is left up to interpretation what constitutes a major and minor change. What is most important here, is to use a system structure that is flexible enough to cover the types of changes that will be made. If you need a suggestion for which scheme to use, there are a variety of standards available to use including ASME Y14.35M and GOST.

More importantly, it is best to determine that revision scheme beforehand, as changing this mid-stream does cause problems and confusion.

Lifecycle

Not to be confused with the revision numbering scheme, the data item lifecycle stages are something separate. The lifecycle scheme is used to describe the maturity of a specific data item. For instance, electronic products would usually have six lifecycle stages: introduction, growth, maturity, decline, phase‐out, and obsolescence.

The individual names for each stage may vary in your situation. The best managed systems are those that change the lifecycle stage automatically. Secondly, whenever material changes occur, the lifecycle automatically returns to the introduction state. In this way, all changes will be perceived and can be scrutinized. As we will see shortly, these changes must be reviewed and go through an audit process. Those automatic lifecycle changes are useful as markers of the items up for review.

Also, it is important to keep in mind that the lifecycle does not just apply to CAD models or components. Any object in the database can (and should) have a lifecycle.

A- Architecture

What is meant when speaking of architecture? It is the specific structure of the database that governs what data is collected, how it is stored, arranged, and used in a database system. This system will vary depending on your individual needs and environment. The commonality among most databases is the ability to set up a folder structure.

The more structured your database is, the better. As you have seen, there are endless types of electronic components available on the market. How to organize them in a way that makes it easy to find a certain component quickly is vital. A common approach I have used is to locate all the components according to category and family - also known as component taxonomy.

To help organize categories I like to number those in a 100s Series. Then, families are single numbered.

For Example,

With this sort of structure we can easily find and organize any component. But, keep in mind, that the database does not only hold components, but also any other possible information that may be required.

I have seen some elaborate PCB Data Management Systems. But the best systems are not dependent on the size, but rather the quality of the information. The old axiom that “it is not quantity, but quality” holds true. Assuring the quality of a database means conducting constant audits. As mentioned before, a good system will have the characteristic that whenever changes occur to an object, that object’s lifecycle state would automatically change. At this point it’s a good time to conduct an audit. A good rule is to not use those components or trust the information until that audit has been completed.

On the coast of a very rugged area of North Carolina there stands three lighthouses. Opposed to what you might think, when ship captains are piloting into port, they do not go from lighthouse to lighthouse. Instead they line up all three, such that only a single point of light is visible, keeping them in line with the channel. In the same way, during the auditing process we are verifying that all the lights are lined up and we see only a single source of truth. When it comes to components, our document for origination of all truth is the manufacturer datasheet; every data element must line up with that. If not, then we are setting ourselves up for problems down the road.

T- Tailored

The final pillar that supports every stable PCB Data Management System is that it is tailored. As we saw in Chapter 2, there is a massive paradigm shift occurring within the entire electronics industry. That forces us to remain adaptable, to not set anything in stone. The database system must be flexible enough to adjust with the changing tide of our industry.

As this information shifts, we need to be prepared to identify the changes and how they will be implemented. In doing so, the lifecycle of any data item in question (symbol, footprint, component, schematic page, etc.) will advance or revert back to the state where it can then go through the review (audit) stage. No changes that impact the information should be done without some sort of documentation as a form of validation to the change, but the PCB Data Management System will in the very least automatically track all history of each item, providing a clear audit trail.

Learn more in the OnTrack Podcast with Judy Warner and guest John Watson, watch the whole episode here: