Rocketing into the Future with Apollo Fusion and Altium

Space is a uniquely punishing environment, from extreme temperatures to high levels of radiation. Anything designed to operate in space has to be more than just tough—it has to be virtually indestructible.

Apollo Fusion, a Bay Area startup, develops propulsion systems for satellites that provide global connectivity. Their Power Processing Units (PPUs) are built with the uniquely harsh environment in mind, rugged and radiation-tolerant for ongoing operation inside thermal vacuum chambers or in orbit around the earth. The PPUs are highly efficient. They maximize the amount of spacecraft power available to the Apollo thrusters, and they minimize the size of solar panels and batteries required.

To ensure that their PPUs can hold up under extreme conditions, Apollo Fusion has to test their propulsion systems for just about everything, from radiation, to shock, and random vibration. The electronic components, including the PCBs, have to withstand the rigorous testing.

For a startup company, maintaining a level of transparency is essential from an investment perspective. Management communicates with investors regularly, and with their old system, the information conveyed wasn’t always as up to date as is now possible. With the first major launch on the immediate horizon, Apollo Fusion needed to find a way to connect their R&D team, management and investors quickly and easily, ensuring all key stakeholders had the most accurate, up-to-date information on product development.

And that’s where having Altium Designer, empowered by Altium 365, came in handy.

Bringing Everyone on Board

Apollo Fusion started out as a single component product company and they quickly began manufacturing multiple robust, lightweight propulsion systems. An expanded product offering quickly outgrew both their initial business model and their existing software tools.

As Tejesh Makanawala, Director of Power Electronics at Apollo Fusion, elaborates, “Before, we had multiple libraries and our engineers were using different programs. All of the part libraries were on the desktop, which was really restrictive, not easily accessible by multiple stakeholders and often introduced inaccuracies during the PCB design phase. It seemed like there was a wall between our electrical engineers and mechanical engineers because we weren’t connected, so collaboration wasn’t easy.”

With the power of Altium Designer and Altium 365, Tejesh and his team could finally connect at every stage of product development, as well as all of Apollo Fusion’s stakeholders, ensuring everyone always had access to the most accurate information at all times. Accuracy was essential across the entire organization, especially for management. “With a startup, if a product succeeds, everyone in the company succeeds,” Tejesh explains, “Management communicates with investors regularly, and with our old system, the information conveyed wasn’t always accurate.”

“Credibility is a big factor at Apollo Fusion. Our CEO is very involved with what we do, so Altium 365 helps him stay in the loop. Management can get insight into how projects are progressing, which has significantly increased the timeliness and comprehensiveness of their reporting to our investors,” Tejesh adds.

Data Management Redefined

Altium 365 didn’t just bring everyone at Apollo Fusion together—it also coalesced their specialized part libraries and allowed for easy exporting of data into thermal analysis software. As Tejesh explains, “ Having this collaborative element has been a real godsend for us.” With an ever-expanding parts and component library, being able to add new parameters is especially helpful for Tejesh and his team. Altium Concord Pro, on the Altium 365 cloud platform, makes part additions almost effortless.

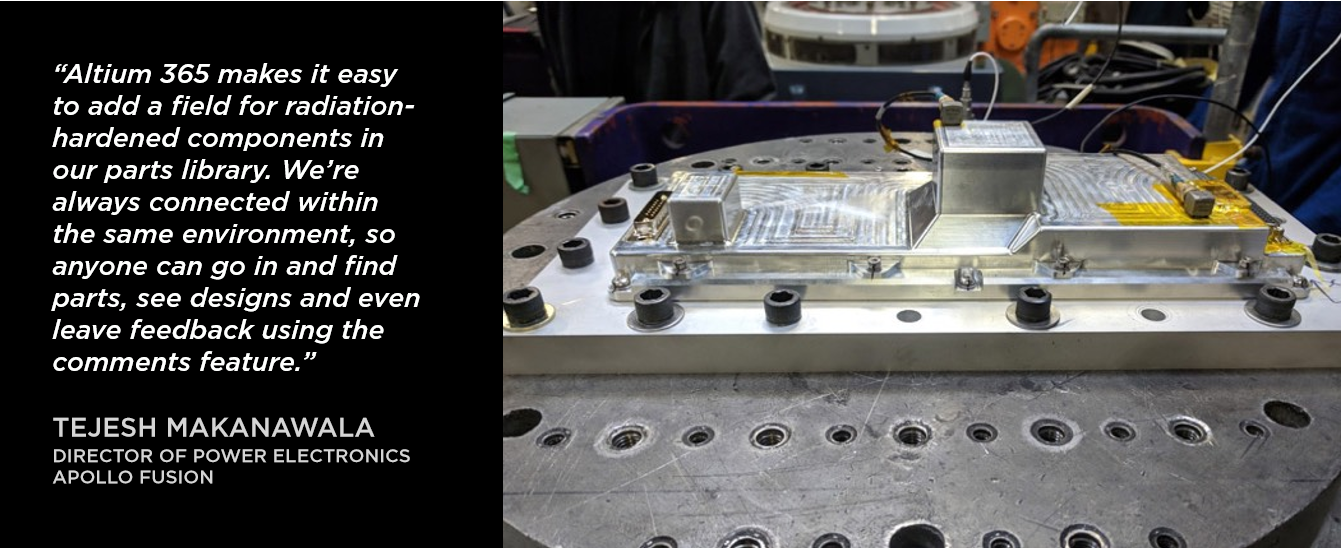

“Altium 365 makes it easy to add a field for radiation-hardened components in our parts library. We’re always connected within the same environment, so anyone can go in and find parts, see designs and even leave feedback using the comments feature.”

With Altium 365 powering their progress, Apollo Fusion’s PPU boards and Hall thrusters can go from the Earth into orbit, enhancing satellite mobility, functionality, and even end-of-life orbit change. And that’s good news for everyone, from Apollo Fusion and their customers to everyone who relies on their satellites to power everyday life.