Rising to the Occasion with Altium Designer + Altium 365

Altium has been essential to the PCB design world, empowering electrical and mechanical engineers with the tools they need to design the electronics we rely on every day. But what happens when everyday life itself is completely disrupted by a global pandemic?

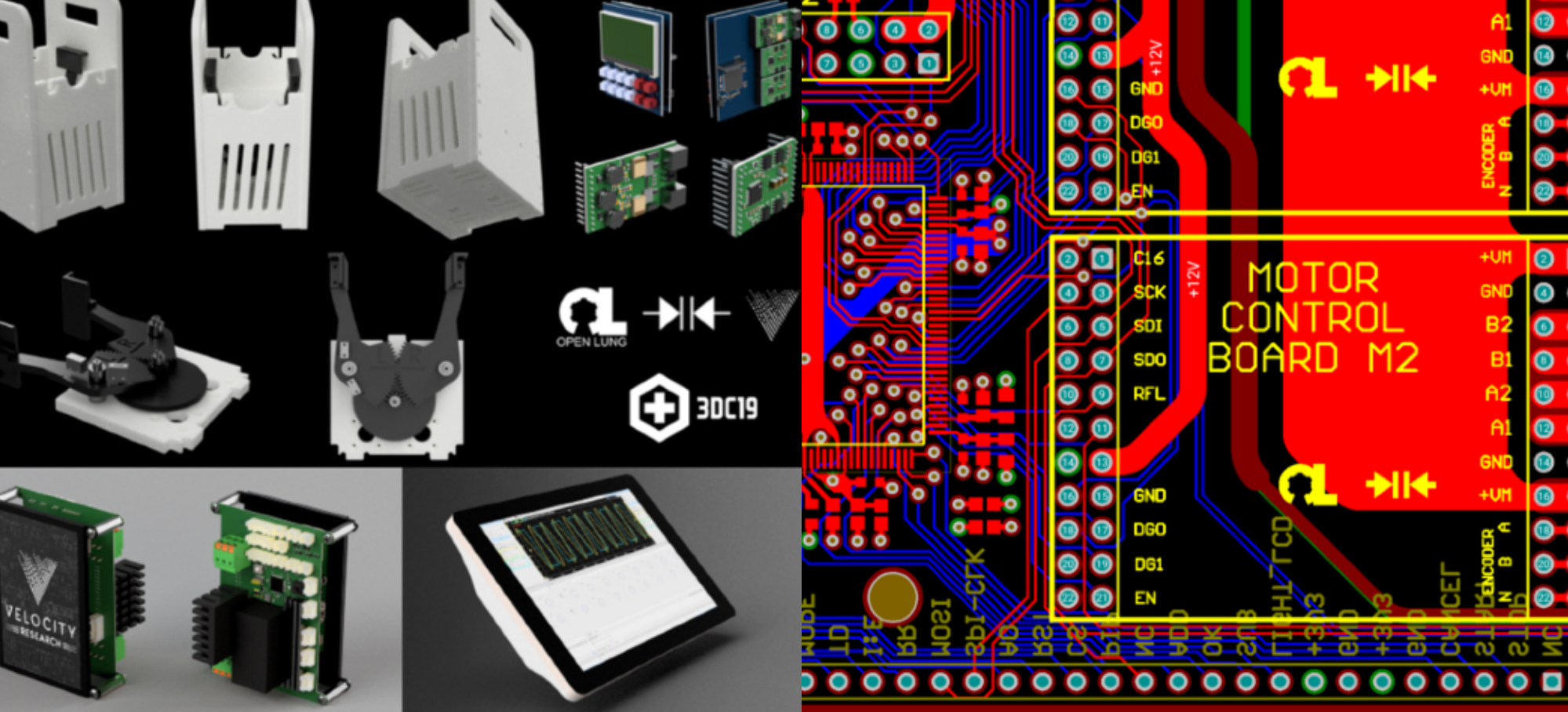

As the world grapples with the worst pandemic in over a century, millions have risen to the challenge to help others, especially those in the healthcare industry. Since early 2020, the outpouring of support to help offset the strain on the medical supply chain has been unparalleled, across multiple industries. One of the more notable projects to arise during this time of crisis is the Open Source Ventilator Project, a global coalition of engineers, designers and medical practitioners, committed to creating low-cost Field Emergency Ventilators (FEVs) made using 3D-printed components with attached bag valve masks.

These FEVs are far lighter and less expensive than traditional ventilators, which can cost upwards of $50,000 and take months to manufacture; the Open Source Ventilator Project designs cost $600 and can be produced quickly. Altium Designer with Altium 365 has been an important part of the project’s success. Altium 365 makes it possible to share PCB designs and collaborate with anyone - in any time zone, at any company - as the design evolves, empowering the kind of global collaboration necessary to move ambitious aspirations like the Open Source Ventilator Project forward.

Empowering the Impossible

The Open Source Ventilator Project began inauspiciously enough out of Ireland in early March 2020 to help support COVID-19 patients in emergency settings. Initially, it attracted just a few volunteers, but word spread quickly throughout the global engineering community. By mid-March more than 300 different companies, individual engineers, medical device designers, and programmers from all over the world were heeding the call. As March drew to a close, the group’s size had surpassed 3,000.

Among the first wave of respondents was Velocity Research; an engineering services start-up based in Michigan, headed up by Founder and CEO, Dugan Karnazes who also happens to be an electrical engineer.

Knowing he had the experience and the background, wanting to help, Karnazes reached out, but had no idea how big his efforts—or his team—were going to get.

As Karnazes explains, “When I got involved, I thought maybe I was going to design a circuit with just a few people; before I knew it, I had hundreds more volunteers. I wound up working with the team in Ireland to help organize the project, putting the call out on my end. Over 800 engineers responded.”

When selecting his team from a large pool of applicants, he looked for engineers with the right set of skills and experience, as well as knowledge of Altium Designer. With over 800 volunteers, Karnazes had his work cut out for him; by focusing on this criteria, he was able to select his team of 40 and they got to work.

Coincidentally, Karnazes began to use Altium 365 to streamline PCB design at Velocity Research. The cloudbased platform that works seamlessly with Altium Designer to empower design sharing and collaboration with anyone, wherever they are, in whatever time zone, at any company, as designs evolve. Altium 365 was essential in bringing the team all together. As Karnazes elaborates, ‘When you have 3,000 people working on a project, labor and software is unlimited; the only limitation is time. We needed close collaboration with this many people, working from all over the world, all working from home, and Altium 365 helped pull everyone together.”

Altium 365 works harmoniously with Altium Designer; all Karnazes had to do was send his various team members an email with login information.

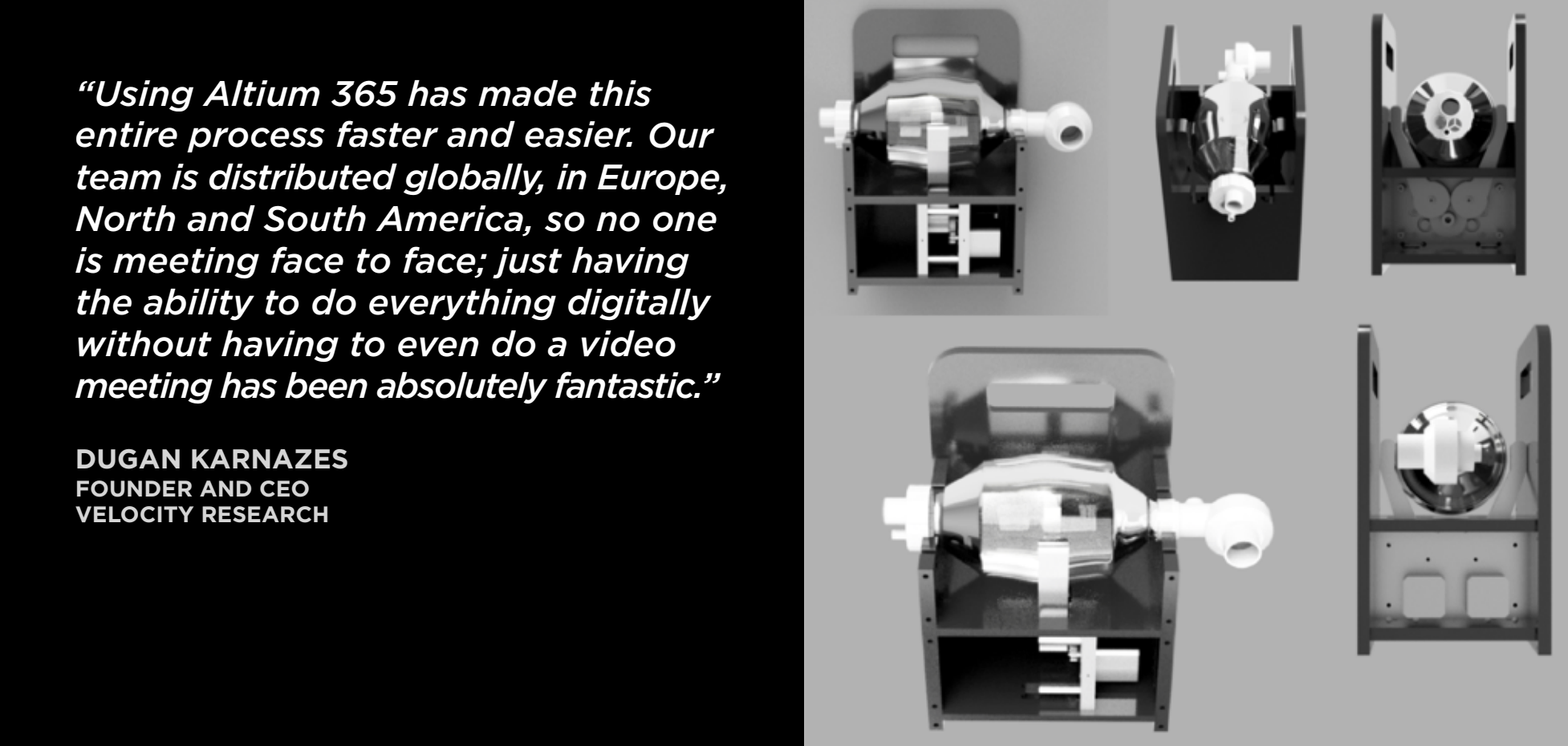

“Using Altium 365 has made this entire process faster and easier. Our team is distributed globally, in Europe, North and South America, so no one is meeting face to face; just having the ability to do everything digitally without having to even do a video meeting has been absolutely fantastic,” elaborates Karnazes.

Eliminating Exporting and Sharing PDFs When Every Second Counts

Altium Designer knowledge was essential for Karnazes and his global team of electrical engineering volunteers in order to design PCBs, but Altium 365 brought the entire team together - from project managers for mechanical engineers, to manufacturing facilities.

As Karnazes explains, “We’ve been working with people with lots of different backgrounds, all added to the server. We’ve had engineers, people with medical device experience, firmware specialists—and all I’ve had to do is send them an email so they can get started. With the exception the engineers in my company, no one else on his team of volunteers had been using Altium 365; they were only familiar with Altium Designer as a standalone program.”

Altium 365 has also helped make collaboration effortless. With cases of COVID-19 growing exponentially across the world, the need for production-ready, low-cost, easily producible FEVs increases every single day, making Altium 365 a real lifesaver.

“I’ve not emailed a single .pdf since this project started—it’s all there inside Altium 365. All I did was send out a simple instruction email to anyone joining our team —‘Log in here, I need your email, I’ll add you to the account and you should see this, if you have any problems, just let me know’—no one had any problems.”

For team members with diverse backgrounds, Altium 365 helped illuminate different aspects of the project to everyone involved. “People who hadn’t done version control before were able to learn and implement it easily. We have designers from all over the world, all working at home digitally, so there are no borders anymore. Giving them access to one workspace inside Altium 365, versus exporting files and emailing them back and forth, has been really essential to the speed of development,” adds Karnazes.

The team was able to pull together four prototypes within mere weeks, with just one 3D printed component to empower mass production. “We got our design in front of Spectrum Health for medical guidance; with the help of our manufacturing partners we now have the capacity to produce 500 ventilators per week for deployment in South America, Africa and everywhere else they’re needed.”

Until Normalcy Returns

With normal life on pause, Velocity Research has donated all of their efforts and labor to working with the Open Source Ventilator Project.

To date, the project has grown exponentially, producing ventilators around the world. In the U.S., Karnazes and his team have partnered with Ford, GM and Boston Scientific to acquire FDA approval.

For Karnazes and his team, the project has grown beyond ventilators. Using 3D printing, they’ve been able to produce and donate over 30,000 face shields and other essential personal protective equipment (PPE) to healthcare workers worldwide. By reducing all of the back and forth and exporting that normally goes into a collaborative process, Altium has helped the Velocity team and the rest of the Open Source Ventilator Project go from concept to production.

And when life returns back to normal, Karnazes and his team will continue to rely on Altium Designer and Altium 365. “The Altium 365 platform has dramatically changed how fast we’re able to adapt to changes in terms of collaboration with remote and local teams. I can’t imagine not having it,” concludes Karnazes.