PCB Prototype Board Layout Software Designed to Work in Unison

When you’re ready for PCB manufacturing, you need to create a set of deliverables from your PCB layout files. All PCB manufacturers and PCB assembly services will use your layout data and a set of other documents to get your board into the manufacturing process. You shouldn’t need separated design and PCB fabrication tools to get your board into production. Instead, you need to use a complete application for design and manufacturing in a single program. You’ll find these features and many more when you use Altium Designer.

ALTIUM DESIGNER

Professional PCB design software for preparing your circuit board for manufacturing.

The traditional process for PCB prototyping moves from building a PCB layout with CAD software to fabricating a prototype. After prototyping is successful and the board passes a series of tests, the board can be put into full-scale manufacturing. Getting through each of these stages requires the right set of design tools that help you prepare for prototyping and eventually full-scale manufacturing.

Designers looking for PCB prototype services need to create high-quality, standardized deliverables for PCB manufacturers and PCB assembly services to reduce turnaround time and ensure scalability. Your circuit board design software needs to include some important tools to ensure your components can be sourced, your boards can be fabricated, and assembly can be completed with high yield. Here’s how the unified design features in Altium Designer will help you get through the design and prototyping process quickly.

Develop and Evaluate Your PCB Prototypes

Your prototype is the first step in building a functional product and ensuring that it can be mass produced. Your new product will need to go through a battery of tests to ensure it will function as desired in its intended application, and this all hinges on getting the design correct.

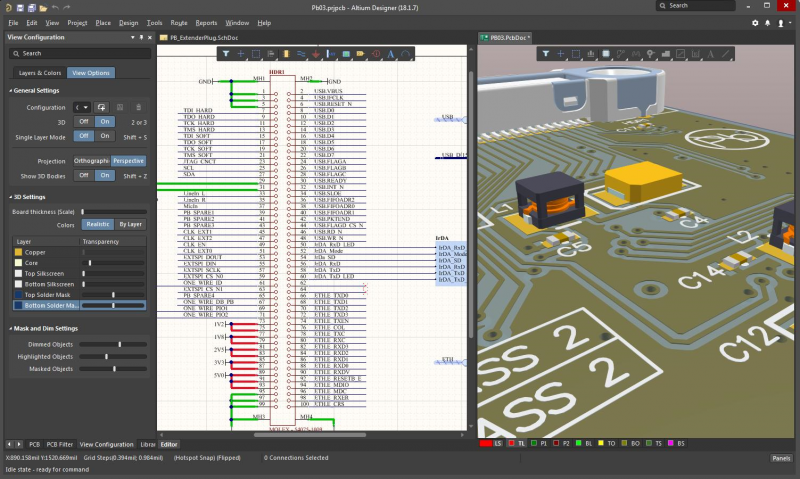

The integrated design tools in Altium Designer help you create all aspects of your design, including schematics and layout. Everything is integrated into a single program, including a schematic capture utility for transferring from schematic to a new PCB layout. You’ll also have access to pre-layout and post-layout simulation tools to help you verify your new design.

Use Rules-Checking to Obey DFM Requirements

How can you be sure your boards will not violate any PCB assembly or fabrication rules? You need to use the best PCB design software with rules-checking features and online DRCs to help you quickly spot errors in your board and implement changes to prevent fabrication errors. As you create your prototype circuit board, standard rules for PCB manufacturing and assembly are checked in real-time, as well as custom rules that are specific to your application and design requirements.

These automated DRC tools help you identify errors and correct them before you engage with a PCB prototyping house. In addition, they can catch errors that some prototyping houses may miss, especially errors that are specific to your board application and design requirements. This saves you time and cost when you’re preparing a circuit board for PCB prototyping and, eventually, full-scale manufacturing.

- If you can spot design problems before you send your design to PCB assembly services, you’ll cut down your lead time and expense.

Learn more about common SMT process defects you can spot in your board layout.

- You can make sure your board quickly hits the PCB assembly line when you program the right design rules into your PCB design software.

Learn more about DFM checks before PCB prototyping with Jay Colognori.

- PCB layouts need a complete set of rules checks as they are created. Altium Designer’s rules-driven design engine helps you check your circuit board layout choices in real-time and prevents design errors.

Learn more about online PCB layout rule-checking in Altium Designer.

A PCB prototyping service will need to see all your design data to ensure your board can be produced with high yield.

Starting the PCB Prototyping Process

The best PCB design software will help you generate the files you need for your next prototyping run without requiring an external program. Before your design can be put into production with a PCB prototyping service, a set of standard deliverables needs to be generated from your design data and sent into your fabricator for a DFM check. Designers need to create the following set of deliverables:

- Gerber files generated from your PCB layout in standard formats (RS-274-X or X2)

- A bill of materials with complete procurement information, component descriptions, and acceptable alternatives

- PCB testing data and testpoint descriptions

- Pick-and-place data for programming automated assembly machines

- NC drill files for placing vias and mounting holes in the PCB stackup

- An IPC-compliant netlist that is used in automated testing and for layout verification

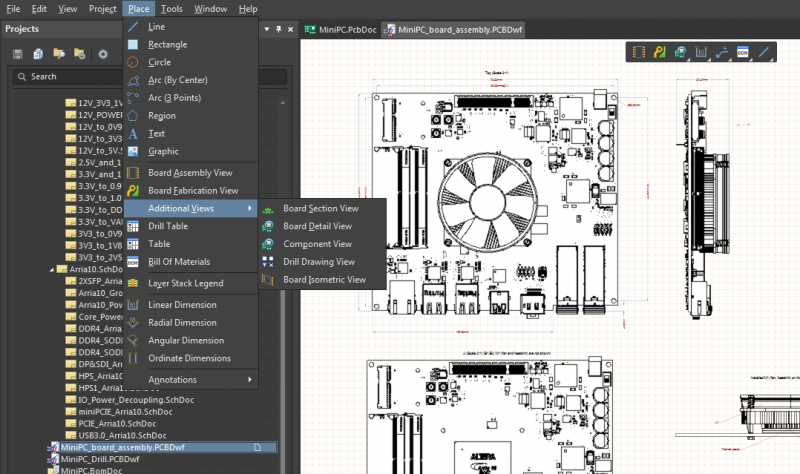

- Fabrication and assembly drawings showing a PCB stackup, component locations, reference designators, and fabrication notes

Once you generate these files, your data can be sent into a PCB prototyping service to begin quoting and DFM checks. Most manufacturers that have a user-facing quote portal will be able to provide very accurate quotes once you upload your design files. Once the design passes DFM, you can begin procuring components and consign them to an assembly house. The best PCB design and layout software will help you move through this process faster as you can quickly generate these standard deliverables before you get a quote for your design.

Types of PCB Prototyping Services

Prototyping is an important step in product development, and it gives you a chance to test the functionality of your PCB before it's deployed in a production environment. There are many PCB prototyping services that offer varying levels of service, price ranges, and lead times. The prototyping service you use might only be a fabricator, meaning you'll need to contract with an assembly house in order to finish and receive your PCBA prototype.

Make sure to pay attention to the lead time for your prototype as some services offer different options. There are many rapid prototyping services that aim for the shortest possible lead time on your fabricated boards, but these services will be more expensive than other PCB prototyping services with long lead times. Rapid prototyping services will use standard stackups to eliminate NRE tasks and expedite your board with standard in-stock materials. In addition, make sure you plan for assembly with an external service if needed as not all rapid prototyping services will offer PCB assembly in-house.

Create Standardized Manufacturing Documentation

Preparing your prototype design for fabrication and PCB assembly services works best with software that instantly exports your design data into standardized formats. Altium Designer instantly takes your design data and generates the fabrication files your manufacturer will use to create your new circuit board and prepare it for PCB assembly.

- Your PCB manufacturing documentation gets used to manufacture prototype boards and to manufacture at scale. You’ll need to send a complete documentation package to your fabricator and PCB assembly services.

Learn more about creating your manufacturing documentation with Duane Benson.

- Your bill of materials contains critical information for sourcing components and PCB assembly. When you need to create this document for your prototype circuit board, don’t use a premade template, use the best design software instead.

Learn more about the downfalls of using Excel templates for your bill of materials.

- With the supply chain management tools in Altium Designer, you don’t have to worry about having your manufacturer source components for your prototype boards.

The Draftsman utility in Altium Designer lets you instantly generate drawings for your board.

Altium Designer’s PCB Editor Enables Easy Design and Manufacture

When you use Altium Designer, you can bring design concepts from the lab into PCB prototyping and PCB assembly quickly and easily. Your PCB layout features integrate with a complete set of manufacturing features, giving you the features you need to make the transition from prototype boards to a final product produced at scale. Everything you need to create high-quality PCBs and produce them at scale can be found in Altium Designer.

PCB Prototyping is Unified with the Layout Tools in Altium Designer

Altium Designer eases the process of PCB design with hierarchical multi-channel design support. You can create sections of circuitry once and then instruct the software to repeat all the components and connectivity in hierarchical schematics. When you use the integrated schematic capture tool to transfer the design from the schematic editor to a PCB Layout, Altium Designer automatically steps out the physical components and nets the required number of times.

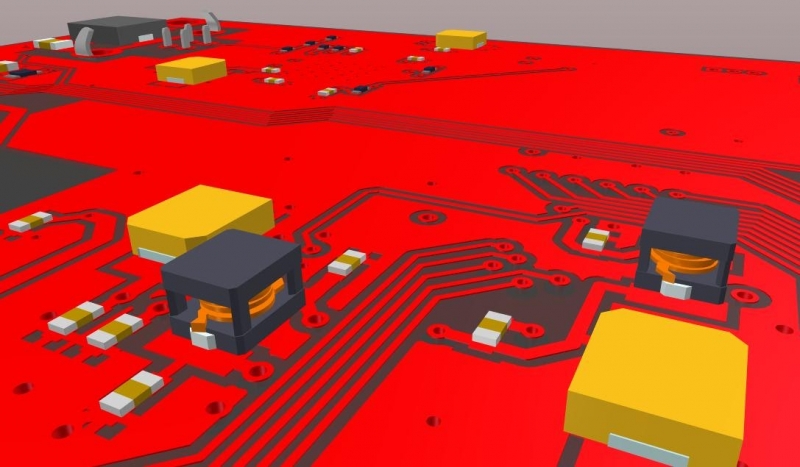

After determining the PCB layout you use Altium Designer’s 3D layout mode to view your PCB in 3D and check that your prototype will fit within your enclosure. Once you’ve verified your design, you can generate fabrication documentation for PCB prototyping and PCB assembly. Once you’ve tested your prototype boards, you can quickly scale to a high-volume PCB manufacturing process.

- Only Altium Designer integrates a complete set of design and manufacturing tools into a single application. You’ll have the design features you need to prepare for prototyping and manufacture boards at full scale.

Learn more about rules-driven PCB design and manufacturing in Altium Designer.

- The native 3D PCB design features in Altium Designer are ideal for taking your prototype boards and transforming them into high-quality finished products that can be manufactured at scale.

Learn more about the native 3D PCB design features in Altium Designer.

- When you’re working on a prototype PCB assembly for advanced products with multiple designers, the collaboration applications can help you stay organized and help you source components before sending your boards to assembly services.

Learn more about the sharing, collaboration, and data governance features on Altium 365.

Verify your design in 3D with Altium Designer

When you need to complete your PCB design and prepare your board for the PCB fabrication process, you need the complete set of design, layout, and manufacturing tools in Altium Designer. No other PCB design platform gives you the capability to fabricate a prototype board, production boards, and PCB assembly services data in a single program.

Altium Designer on Altium 365 delivers an unprecedented amount of integration to the electronics industry until now relegated to the world of software development, allowing designers to work from home and reach unprecedented levels of efficiency.

We have only scratched the surface of what is possible to do with Altium Designer on Altium 365. You can check the product page for a more in-depth feature description or one of the On-Demand Webinars.