PCB Library and Supply Chain Integration in Altium Concord Pro

Anyone planning to manufacture a new circuit board has plenty of challenges to overcome. From component shortages to outdated design data, project managers and designers face obstacles to timely production that arise from stale component data and supply chain information. Sourcing shouldn’t be guesswork, and it shouldn’t require 3rd party tools that only provide visibility to a portion of the supply chain.

Supply chain changes can catch any designer or project manager by surprise. These changes delay prototyping or high volume manufacturing run by weeks or even months. Project managers need tools that give them full supply chain visibility as this aids manufacturing planning and design. With Altium Designer and Altium Concord Pro, you’ll have full integration among your circuit board design tools, components libraries, and supply chain visibility features. No other platform provides this level of unification.

ALTIUM CONCORD PRO®

A unified data management and supply chain visibility platform that integrates with Altium Designer® and other mechanical design tools.

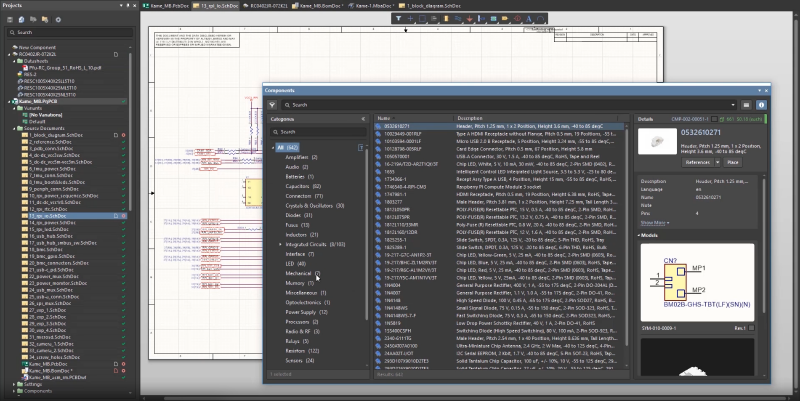

Don’t let the buzz-words fool you: supply chain integration is about more than just getting a peak at distributor databases. With most designers using personalized PCB libraries to track data for components, they put themselves at risk of data going stale, and they may even fall victim to the infamous “footprint not found” error. Sourcing data, models, and footprints for components are periodically updated, but design engineers may not have access to these important updates without a solution that integrates circuit board design tools, PCB libraries, and supply chain visibility features in a single interface.

Design engineers and project managers need the right schematic design and PCB layout features to create their circuit boards, but they also need tools that integrate component sourcing data alongside their design tools. This sourcing data also needs to be updated in PCB libraries in order to ensure that all members of a design team have the most current component footprints, models, and sourcing data.

With Altium Concord Pro, you can increase your design productivity with Altium Designer as you move through the design process and onwards to manufacturing. You’ll have access to real-time supply chain information and updated component data with a managed solution. You can anticipate and plan for supply chain changes instead of reacting to them and ensure your next product is competitive.

Integrated PCB Libraries and Managing the PCB Supply Chain

Managing the supply chain for your next product and your PCB requires real-time information on obsolescence, lead times, costs, and available replacement components throughout the supply chain. Your component libraries provide critical data for your designs and allow multiple members of a design team to access the same information. The is great for collaboration and allows anyone to reuse a consistent set of data in new designs.

Although this type of collaboration and design reuse is much easier when you use PCB libraries, your design teams are at risk of lost productivity due to changes in the supply chain. Changes in the electronic component supply chain due to obsolescence or depleted inventory inevitably require redesigns before sending your board off for manufacturing. The best way to solve this important problem is with a managed database solution that provides continuous updates and to component data and the supply chain.

Working with PCB Supply Chain Data

While component libraries that continuous update with new supply chain integration help solve a number of problems, it can be difficult to instantly take advantage of this information in your design tools. Most PCB design programs make it difficult to import these data changes into your designs because they do not directly integrate with database management tools.

Other design platforms that do offer database management tools still separate these features into different programs, making it difficult to really integrate supply chain data into your designs. You’re stuck moving back and forth between a design program and a database tool. If your design platform doesn’t offer this type of feature, then you’re stuck manually updating your database and libraries with current supply chain data, or your left to find a 3rd party tool that doesn’t give you a complete view of the component supply chain.

Larger electronics companies and small service bureaus can reap real productivity benefits when they have access to a managed supply chain solution that integrates with their PCB libraries and design features. This gives you access to design features, PCB libraries, and sourcing data in one location: within your design software.

- You can stay on top of changes in the sourcing landscape when your libraries include receive instant updates. This ensures you have the latest schematic symbols and PCB footprints for use in your next product.

Learn more component libraries that provide real-time updates.

- You don’t have to be part of a huge company to have access to information throughout the supply chain. A managed supply chain visibility solution also helps keep costs in check by reducing preventing redesigns, turnaround times, and providing cost comparisons.

See how you can control costs with real-time supply chain visibility tools.

- In the event of obsolescence, you need tools that allow you to quickly grab available replacement components and import them into your designs.

Learn more about replacing obsolete components with search tools.

Real-time supply chain control with Altium Concord Pro

Problems in PCB Supply Chain Integration

The main problem with supply chain integration isn’t getting access to current data. If you subscribe to the right 3rd party services and spend enough time on component distributor websites, you can find the data you need. The real problem is immediately accessing that data within your design software. 3rd party solutions aren’t really solutions because they cannot provide the required level of integration.

Avoid Redesigns with Real-time Supply Chain Integration

When you have a managed solution for retrieving component data and supply chain information that integrates with design tools, you can quickly replace components and create documentation with current sourcing information. With supply chain information instantly accessible in your design software, you can ensure that your new product only contains the newest and fully sourceable components. You can also easily update an older product with newer components or features when you have instant access to current component data.

Having current supply chain information is not just important when designing a new product, it’s also important when it comes time for manufacturing. Keeping on top of changes in the supply chain and securing orders on your own can prevent long turnaround times, ensure your components are authentic, and helps you avoid redesigns prior to manufacturing. The last thing anyone needs is to send a board off to a fabricator, only to be told that the raw materials and components are unsourceable.

- Data management solutions that provide sourcing and traceability data can help you anticipate and adapt to changes in the supply chain and component shortages.

- Component sourcing doesn’t need to be a difficult, manual process.

- Integrated design tools that offer supply chain information also help you generate thorough and current documentation and deliverables for your manufacturer.

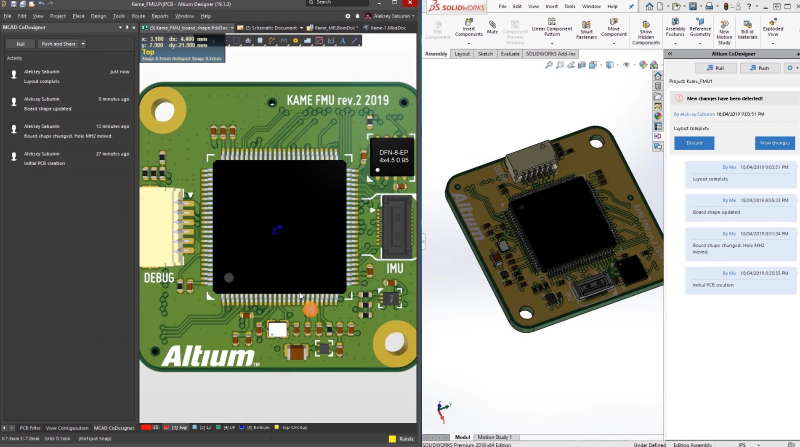

ECAD/MCAD codesign with Altium Designer and SolidWorks

How Integrated PCB Component Libraries Boost Productivity

If you have tools that integrate supply chain information directly into your PCB libraries, You won’t have to resort to working with third-party tools to ensure your designs only contain compliant components. You can anticipate component supply chain problems instead of reacting to them, and you can plan your sourcing strategy accordingly. This helps you avoid extended lead times and manufacturing turnaround times. You can go to market sooner with your desired components when you use a managed solution for component sourcing and supply chain integration.

Altium Concord Pro is the only managed component database platform that integrates directly with the industry standard design tools in Altium Designer. Component data updates will quickly pass to your schematic and layout, and you can quickly access sourcing information at the click of your mouse. Placing these tools in a single interface improves your productivity, helps you control costs, and updates your component libraries with the most current sourcing information.

Enhance Altium Designer with Altium Concord Pro

With Altium Concord Pro, project managers and PCB layout designers have the tools they need to ensure the components that appear in their designs are fully traceable and are up to date. The infamous “footprint not found” error that plagues other design programs is solved thanks to the unified data model that drives Altium Designer and Altium Concord Pro. These features are easily accessible within Altium Designer and are integrated alongside your standard PCB layout and manufacturing planning features. You’ll never need another piece of 3rd party component management software.

The level of integration provided by Altium Concord Pro does not stop there. The native MCAD tools in Altium Designer use the same component model and footprint updates provided by Altium Concord, ensuring component information and mechanical models are fully up-to-date. These supply chain integration tools also synchronize with other programs like Autodesk Inventor and SolidWorks as plugins. Other ECAD and MCAD tools offer little in the way of data management, and they offer nothing to aid supply chain integration and visibility. You can rest assured that your libraries remain fully updated when you complement Altium Designer with Altium Concord Pro.

- Altium Designer’s unified design environment only improves with the data management and sourcing tools in Altium Concord Pro. The rules-driven design tools in Altium Designer use the same data model supplied by Altium Concord Pro. This helps prevent design errors that plague other programs.

- Integrating your supply chain information with your circuit board design in Altium Designer ensures your schematics contain the most up-to-date information. Only Altium Concord Pro offers this type of integration.

Learn more about rules-driven schematic design in Altium Designer.

- Altium Concord Pro allows you to easily organize your component information and replace obsolete or unavailable components instantly. You’ll have real PCB library and supply chain information with Altium Concord Pro.

Learn more about enhancing Altium Designer with Altium Concord Pro.

Altium Designer’s capabilities can now be expanded even further when you use Altium Concord Pro. These two products form the only platform that includes a managed data solution for PCB library and supply chain integration. The schematic editing, PCB layout, documentation, and production planning tools in Altium Designer have instant access to the data provided by Altium Concord Pro.

Altium is invested in your success and provides you the tools and resources you need to be successful. You’ll have access to the AltiumLive forum, podcasts and webinars with industry experts, design tutorials, and an extensive knowledge base. You’ll have the resources you need to quickly rise to expert level and produce cutting-edge technology.

Altium Designer is the only design software platform that integrates the industry’s best schematic and printed PCB layout features with supply chain visibility tools. Placing your data management and component sourcing tools alongside your schematic and circuit board design features boosts your productivity and helps prevent unnecessary redesigns. You’ll remain more competitive and move to market quicker with Altium Concord Pro.