Moisture Sensitivity in Electrical Components

A range of materials used to construct electrical components can absorb moisture from the air over time. This initially became a problem with introducing reflow soldering, where the components are subjected to sudden high temperatures over a short period. This was then exacerbated with the switch to lead-free solder, which resulted in higher peak temperatures during the reflow process. Other factors that have increased the prevalence of moisture sensitivity are cheaper and thinner materials such as plastics, which have more inferior properties than the more expensive hermetic materials that were traditionally used.

The moisture can vaporize and cause damage to the components. This may be in the form of micro-cracking that weakens the component package, complete cracking leading to separation of parts of the component, or surface peeling between a die pad and its resin cover. Whatever the type of damage, the result is that the component will need to be replaced.

One of the challenges is that the damage caused by moisture vaporization may not be immediately apparent and only appear once the device has been assembled and tested. It may potentially be minor enough that the device seems to work correctly simply to fail prematurely when in service subsequently. Usually, cracking occurs where the package is thinnest, which for surface mount components is typically on the underside closed to the PCB and, therefore, out of sight. Similarly, micro-cracking, unless at the surface on a visible part of the component, will also not be visually apparent.

The main problem is the damage caused by moisture vaporization in microcontrollers and other complex devices. The delicate metal wires from the die and the surface mount pads are usually encapsulated in plastic. Any cracking of this packaging could fracture a wire, which would only be detected once the MCU operates unless it’s a power supply pin.

How common is this problem?

The likelihood of this problem occurring is down to the types of packaging materials used and the length of time the component is exposed to moisture. This is primarily down to how long the component is in storage, how it’s protected, and in what environmental conditions it is stored for the storage phase. Once the component leaves storage and is removed from its protective packaging, this is down to its floor life. This is the length of time it’s exposed to ambient environmental conditions and what those conditions are.

The rate at which moisture can diffuse into the component will depend on its humidity and temperature. The higher the temperature, the faster any moisture present in the environment will penetrate the packaging material. This absorption continues until the moisture concentration in the material matches the moisture concentration in the environment. The higher the relative humidity, the greater the amount of moisture that will be absorbed.

The exposure time during the component’s manufacture and the period after it is assembled onto a PCB ready for reflow soldering can be considered negligible compared to the storage time and the time when it leaves storage up to when it is fitted to the PCB. The key environmental factors are humidity, temperature, and this length of time.

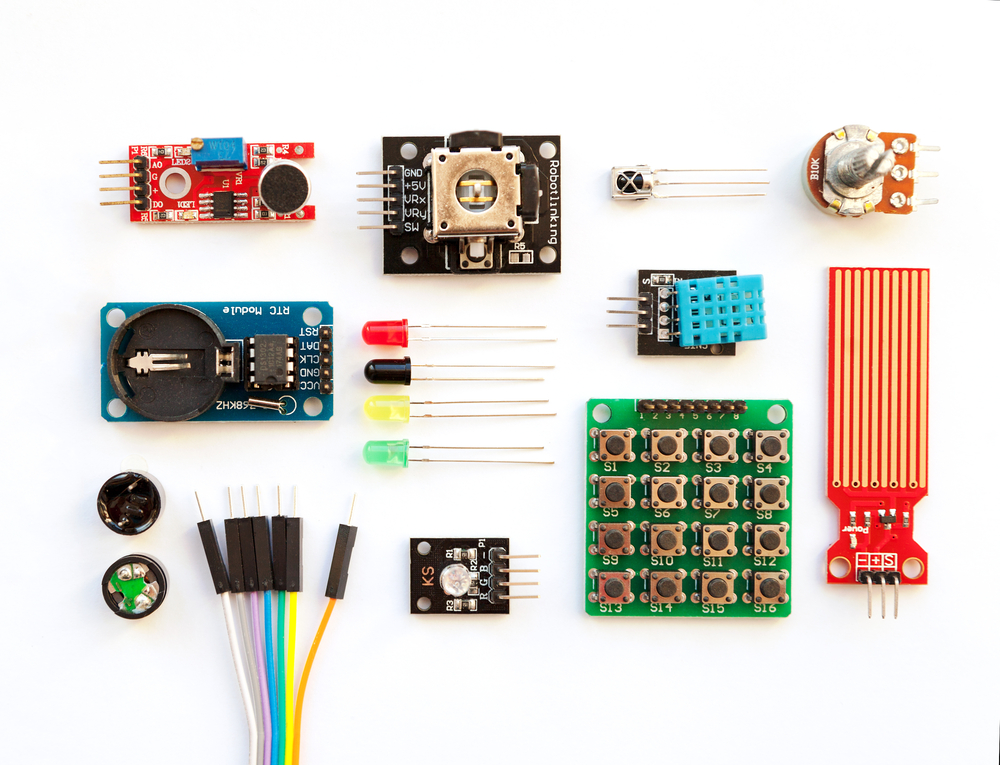

The use of moisture-sensitive packaging materials includes encapsulated components such as integrated circuits and sensors and extends to connectors and the PCB. Only by checking the datasheet for each item in your device will you know for sure which parts are moisture sensitive.

Storage Life

Any components that are sensitive to moisture should be shipped in sealed protective packaging, typically with desiccant gel and an inert environment. The packaging will indicate the maximum length of time that the component can be stored, typically a few years. Parts that are especially sensitive to moisture are shipped usually with humidity indicators included in the packaging to provide a visual indication of the part’s health. As long as the protective packaging isn’t compromised and the storage facility’s environmental conditions are within specification, this should be no different from handling any other component type.

Moisture Sensitivity Level

Standardized Moisture Sensitivity Levels (MSL) have been defined to identify which parts are moisture sensitive. These levels determine how long a component can be exposed to ambient room temperature and humidity level before it will be adversely affected by moisture. Here, ambient is defined as below 30oC and below 60% relative humidity except for the unlimited MSL 1, which is defined as being below 30oC and below 85% relative humidity.

|

MSL |

Floor Life |

|---|---|

|

1 |

Unlimited |

|

2 |

1 year |

|

2a |

4 weeks |

|

3 |

7 days |

|

4 |

3 days |

|

5 |

2 days |

|

5a |

1 day |

|

6 |

Mandatory Bake before use |

What is component baking?

Applying a slow and gentle heat to a moisture-sensitive component can draw out the moisture without causing damage. These components will be subject to baking as part of the manufacturing process before being placed in their protective storage packaging. For components that require baking before use, a repeat of this baking process will gently draw out any additional moisture to “reset” the component’s moisture content before soldering. The baking temperature and length of time the component needs to be baked for will depend on the material used in the component’s manufacture, its thickness, and its moisture content. It is not uncommon for the baking process to take several days.

One crucial factor to bear in mind if you need to bake a component is that the baking process, if not carried out properly, may cause oxidation of the solder pads, which will lead to poor connectivity following soldering.

Will my PCB be affected?

Depending on the type of PCB you’re using, it may well also be sensitive to moisture absorption and suffer similar types of damage during the reflow process. The sensitivity will depend on the materials used to construct the base laminate, the thickness of the materials, the number of layers, and the finished tracking design. Typically, FR4 is considered moisture tolerant, whereas Kapton is moisture sensitive. Factors such as the copper area, tracing thickness, plated through-hole aspect ratios, and the use of surface treatments can all affect.

Managing moisture sensitivity

The general advice is to be careful when handling your components and your PCB, keep them in a low humidity environment for as much of their floor life as practical. Follow the advice in the datasheet and on the packaging, and you shouldn’t go too far wrong. If floor life is an issue, consider investing in a temporary storage solution that keeps everything as dry as possible. Dehumidifying dry cabinets are a great and flexible solution that won’t break the bank. They regulate the interior’s relative humidity, either using active moisture extraction or using a simple reusable desiccant. If money is no object, then a storage solution that replaces the internal air with inert nitrogen offers an alternate solution.

Would you like to find out more about how Altium Designer® can help you with your next PCB design? Talk to an expert at Altium.