How to Create a PCB Manufacturing Cost Estimation

Unless I receive a layout job directly from a manufacturer, my clients will usually ask if I’m a manufacturer. My company doesn’t manufacture boards, but I think it’s important to keep clients informed of the manufacturing costs for new PCBs. Once I started gathering estimates for some of my first projects, I started to better understand the primary cost drivers of PCB manufacturing and how to properly structure a comprehensive estimate for my clients.

Some manufacturers have very convenient PCB manufacturing cost estimation calculators you can use, but the real costs depend on a number of factors. If you’re an entrepreneur and you’re producing your own boards, or you are managing manufacturing, testing, and delivery for a new project, it’s your job to help clients understand the primary cost drivers for new boards. Here’s how you can get an estimate of your fabrication costs, both for local and overseas manufacturers.

What Drives PCB Manufacturing Cost Estimation?

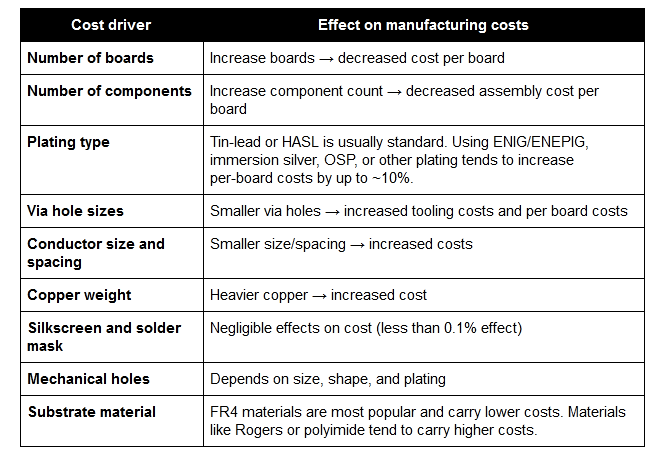

There are a number of factors that drive manufacturing costs. In general, producing more boards, using more vias per board, using smaller traces/vias/mounting holes, and using more components per board will all increase manufacturing costs. However, the costs involved are not linear. In other words, double the number of boards and components will not double the total cost of an order.

There are some important reasons for this. There are a number of fixed costs involved in any manufacturing run, including tooling costs, design review, stencil creation, and others, depending on your requirements. Other costs are variable and are determined on a per-board basis. The cost per board can decrease as order size decreases, which has less to do with panelization. Instead, this cost decrease per board is achieved by amortizing the fixed costs across the entire board run. The same idea applies to assembly (see below).

Here is a short summary of some major cost drivers involved in fabrication. Be sure to consider each of these areas when creating a PCB manufacturing cost estimation.

Testing and Inspection Costs

Testing and inspection are two important activities that also need to be performed when a new board is produced. Production and inspection up to IPC-A-600 Class 3 costs more than Class 2; the same applies to other relevant standards and classes. Manufacturers also offer different levels of design and engineering review during production. Taking advantage of a full engineering review can significantly increase the per-board cost and tends to carry an additional fixed cost. Be sure to inquire what is involved in this type of review and determine which design deliverables you need to provide before adding an engineering review service to your quote.

Assembly Cost Drivers

The cost drivers involved in assembly boil down to the following:

- Number of unique components: More unique components equates to higher cost, although ordering components in bulk reduces the price per component.

- Type of components: All-SMD assembly can cost up to ~50% more through-hole assembly.

- Lead pitch on SMD components: I’ve seen that this varies by manufacturer. If you’re already using all-SMD, some manufacturers will not charge extra for finer pitch components.

- Presence of any BGAs: BGA component assembly can cost ~20% more than other SMD components.

- IPC-A-600 Class 3 and ITAR compliance: Production and assembly up to IPC-A-600 Class 3 can carry significantly higher costs, although the quality of the final product will be much higher. If you’re working in the U.S., your project may need to be ITAR compliant. Finished PCBs will need to adhere to ITAR requirements on data integrity, PCB integrity, and shipping, all of which carry additional costs.

Unless assembly is being done by hand, assembly costs will not increase linearly with the number of boards. In other words, with automated assembly, doubling the number of boards does not double the cost of assembly. Some of the assembly cost goes into tooling and programming machines, while the remainder effectively pays for machine time.

Component costs follow a similar structure. When you order more components, you might reach a new price tier with your component distributor where the cost per component drops. This is one reason it’s better to buy from a single distributor rather than mix-and-match multiple distributors.

Overseas vs. Local

I prefer local manufacturers as it gives me more control over the process. For basic designs, I’ve found that Chinese manufacturers can do the job just fine, although they nickel-and-dime you on small additions to the order (e.g., certain screen printing features, testing, solder mask color). For more advanced designs, or if the design carries some specific testing requirements, I’d rather use a local manufacturer as I can talk to someone on the phone directly.

In terms of cost, the per-unit price for a board produced locally (in the U.S.) can be a factor 5 as large as the price for the same board produced overseas with the same lead time. Assembly is another matter altogether, as not all manufacturers will provide on-site assembly, and you’ll need to get a quote from an assembler company. Having to ship your boards from your manufacturer to your assembler also increases your lead time, which adds intangible costs to your new product.

When you’re building a new PCB, Altium Designer® gives you the tools you need to create products that include advanced features while complying with your manufacturer’s DFM requirements. You’ll also be able to quickly generate fabricator deliverables that aid PCB manufacturing cost estimation

Now you can download a free trial of Altium Designer and learn more about the industry’s best layout, simulation, and production planning tools. Talk to an Altium expert today to learn more.