Evaluating Concord Pro

I’m working on several projects that require new PCB assemblies, and this presented a great opportunity to try Altium’s new product: Concord Pro™. Concord Pro is a component management system which makes component creation and organization much easier than using the current workflow. One of the PCB assemblies I need is a high-current voltage regulator that I will be using for a DC motor controller, and this is the PCB design I will use to showcase Concord Pro.

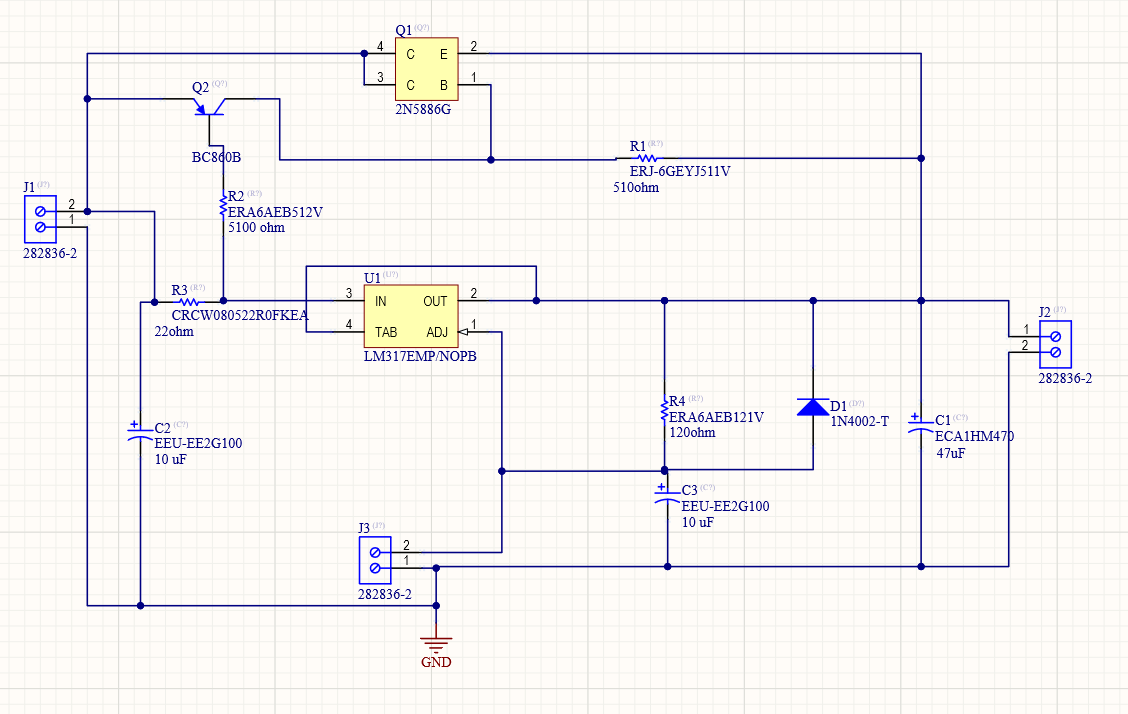

The design needs to drive 12v to 24v motors, and I don’t want the system to be bogged down by current starvation. I’m not really worried about efficiency, and I want to be able to easily adjust the voltage on the fly. So, I chose to create an assembly, one based on the LM317. The LM317 is an LDO regulator, and a staple for power systems. While it is not efficient, it makes up for that in cost, simplicity, and low rail noise.

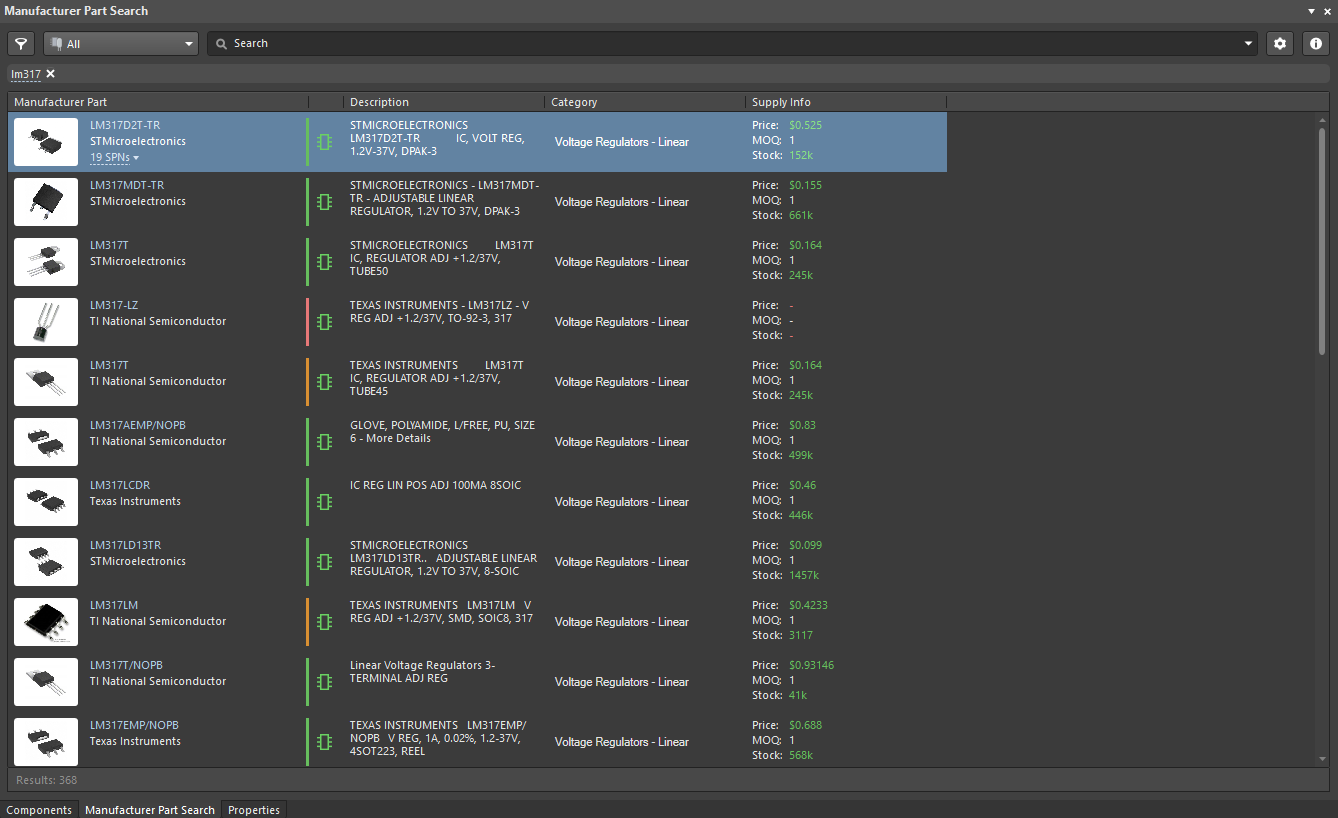

Since I’m using Concord Pro, I’m not going to use an established database. Instead, I’m going to rely on getting the components from the cloud. I started by creating a new project and schematic. Then I logged into Concord Pro and searched for an LM317. I simply clicked on Manufacturer Search and a huge list came up!

I double clicked on the part number with the desired footprint and was directed to the manufacturer’s website. From there, I right-clicked and selected ‘Download’. A pop-up appeared when the download was complete, and I dragged and dropped the component onto my new schematic. Voila!

_2.png)

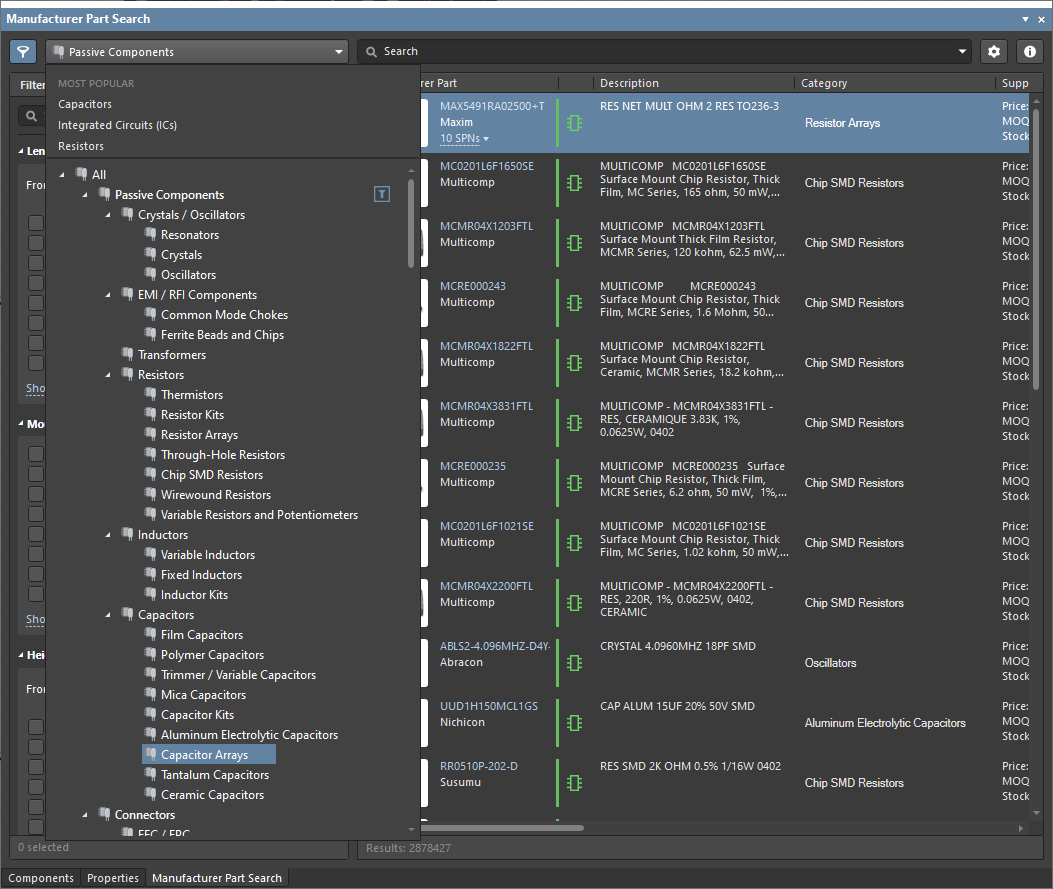

Next, I looked for the first transistor I needed: 2N2905. I saw in Concord that all of them were unavailable. This was confusing since it is such a common part. It turns out that part has been obsoleted. After I stopped reflecting on how old this made me feel, I went to the manufacturer’s site through concord, found a replacement part, and used concord to figure out which version of the part was stocked.

_0.png)

Infinion’s model worked and there was stock at Mouser. I did for the rest of my connectors and ICs. There were several terminal blocks that I needed for the power IOs, a power transistor, and a simple diode. Again, downloading the components as I went and dragging them into the schematic.

.png)

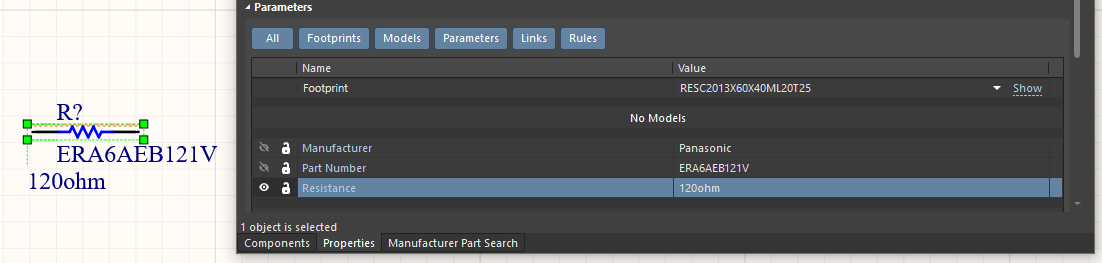

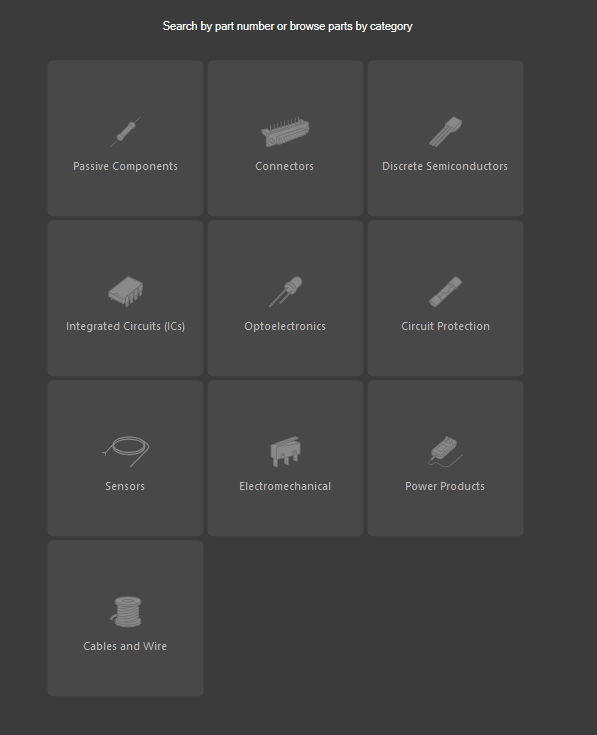

I moved onto the passive components. Since “resistor” is a very generic term, I use the filters to narrow my search based on package size and resistance.

.png)

I found that I couldn’t download most of these components. I noticed there is a symbol that indicates if the part is available from the cloud. When I finally found one that had a footprint, the resistance wasn’t in the part by default and I had to add it as a visible parameter.

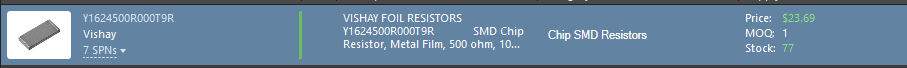

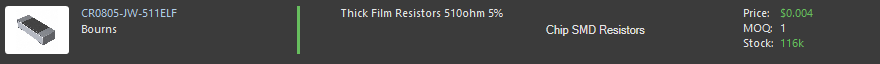

Since I’m basically duplicating TI’s design, I am blindly using all of the values they recommend. I found the 500 ohm resistor was a BAD call. It cost about $20 for the 0805 version because it’s not a standard value.

So I went to the closest standard value, 510, and boom, got what I needed at a fair price.

As you can see by the screen captures, these resistors did not have footprints with them. It was getting obvious that I wasn’t using the intended workflow. I still powered through with this resistor by scrolling until I found a match with a footprint, but wanted to try an alternate approach with the capacitors.

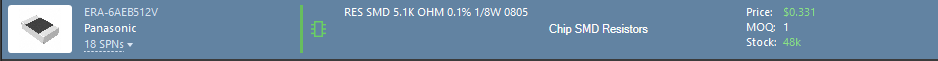

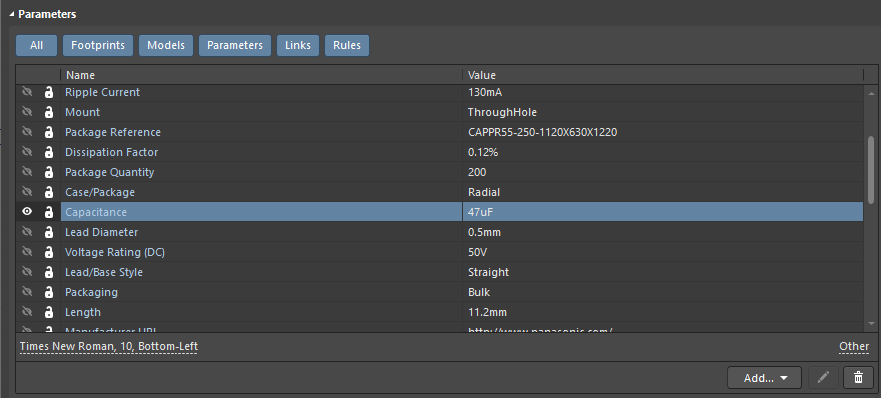

That approach is to use the integrated navigation GUI. I clicked on passive components, then used the filter to search for capacitors. This was obviously the way to go for passive components. The components that showed up were much better supported. All parameters were appropriately filled in and the logical parameters you would typically want visible on your schematic were all setup properly.

At this point, I placed all of the parts, wired up the schematic, then cleaned up the diagram so it was easy to read. At this point, I did everything in about 40 minutes. This is a huge time savings since I didn’t need to create the footprint and schematic libraries or check individual websites for availability.

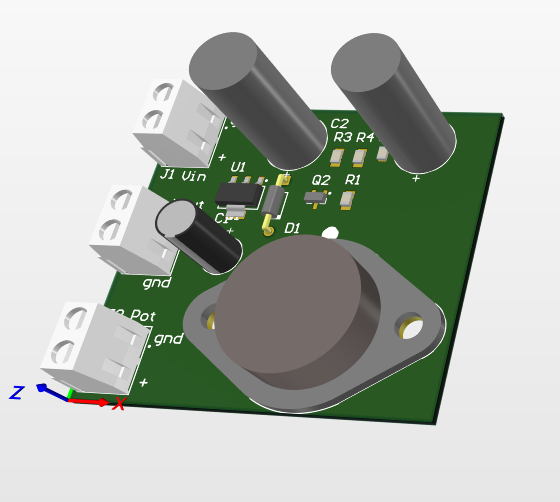

Now I moved onto the PCB. I implemented a two-layer stackup by importing Altium’s two-layer template, placed all the parts, and wired it up. Of course that didn’t involve Concord Pro and that process is very straightforward. Out of curiosity, I checked the 3D visualization and all of the parts included 3D models!

When I evaluate tools, the experience typically feels like I am inflicting some kind of pain upon myself, and I evaluate tools on a fairly regular interval for my employer. I’m sure you all know what I’m talking about. The GUI is not intuitive, finding what you need feels impossible, the output is not in the format you want or it won’t take the inputs you have, getting the tool to do what you are trying to do requires hours of reading poorly written instructions, etc. In the case of Concord Pro, my experience was the complete opposite! After easily wiring the schematic in 40 minutes, I felt energized, and for perhaps the first time, thought “I need this tool”. Ironically, I felt the same way when I recently evaluated Rohde & Schwarz 16-port ZNBT VNA and implemented it at DesignCon 2020, but that is for another blog.

I did find one thing that seemed to be lacking. The origin of the components was not consistent. This made placing components on a square grid painful. It made me think it really wasn’t a Concord problem, but instead an industry problem. I’ve never seen a document that stated where the origin for a symbol or footprint should be. That is probably because tools like Concord Pro are brand new. Perhaps it’s time for someone to step up and create a set of industry standards surrounding PCB libraries for cloud application.

In conclusion, I recommend trying Concord Pro. Given the clear time savings benefit alone, it seems like that could justify its purchase. As an end user, I simply would want it to make my job easier. It feels like it fills a huge and obvious hole in PCB software, and it’s an easy addition for any company or individual.

Would you like to find out more about how Altium can help you with your next PCB design? Talk to an expert at Altium and learn more about making design decisions with ease and confidence.