Sharp Tools to Get the Job Done Fast

“You cannot mandate productivity, you must provide the tools to let people become their best.” ― Steve Jobs

That is some great advice, from a leader in the industry. I would expound on his thought, that it really doesn’t matter how qualified an individual is. They could have gone to the best schools got the best degrees possible. IF… they do not have the correct tools to do the job. The result is an absolute travesty for the company and for the individual. Understand that I not saying education is unnecessary, but rather the education and tools that are used go hand in hand. For example, a trained woodcarver that can-do beautiful pieces of art would have a difficulty time if his only tool in his tool box was a rusty straight screwdriver and a hammer. The correct tools in the hands of a master the possibilities are endless.

In this chapter, we want to go into detail concerning the specific tools and software packages available to support the PCB Data Management area. I will not mince words. The best tool that I have found, after decades of working in this field, for PCB design side is clearly Altium.

For the PCB Data management part is a software package recently put out by Altium called Nexus. Between these two packages you have all the tools needed in a future-proof PCB Design solution. If data management is important in your PCB design process then read on.

Altium

Since 1985 (when they were known as Protel), Altium has been the leader in the PCB Software industry.

With a simple approach, of software development, they accomplished a unified platform which would hold all the required data to design any level of PCB whether it’s a simple 2-layer PCB or an advance HDI Design. What I call the Buffet approach to software. Providing various tools or plug-in modules that allows the designer to pick and choose what is needed on their specific system. This was brought about in 2004 when they developed their own software platform called Design Explorer (DXP). With that, Altium was able to independently develop whatever modules or tools were needed.

Also, with the many company acquisitions, the results have been remarkable growth. It would take more space than we have in this document to even try to describe the history of Altium and how much they have impacted this entire industry. I have come to a major conclusion that everyone at Altium must be major fans of the work of Ralph Waldo Emerson they have fully taken to heart his quote “Do not go where the path may lead, go instead where there is no path and leave a trail”. Altium has done just that.

Nexus

Nexus could be described as the workhorse program for Altium. It has only been released for a rather short period of time. But it has already had a huge impact on how things are done. On one hand, Nexus provides the means to fully support PCB Data Management for various items including components. On the other, a sort of a new area for Altium, but something that was sorely needed. A tool to organize design process flows and the required documents attached to those process’.

With the ability to conduct full electronic versions of Design Reviews. This has really been a new opportunity for Altium to stretch their legs and step out of the specific PCB design software arena and launch into the PCB Design Project Management.

But this was the logical evolution for Altium, when you see that so many different roles/individuals are involved in the process not just PCB Designers or Engineers. To come up with a way to distribute the needed information to those folks. But also, they realized that it really doesn’t matter how good the PCB data was being used if the process was not controlled in some way.

Altium Nexus and the Support of the S.M.A.R.T. Pillars

Anyone familiar with construction will tell you, a pillar is only as strong as the foundation it sits on. We want to examine the specific tools and or features available to aid in setting up and managing a successful PCB Data System. Between several tools in Altium and Nexus all 5 pillars of the PCB Data Management are fully supported.

Pillar #1 - Singularity

During the huge rush sometime or should I say many times of getting a PCB done. It becomes very important to be able to verify this Pillar of Singularity. There always seems to be that one person who still wants to work from their own personal library sneaking in those unmanaged parts. There are several tools available to check this.

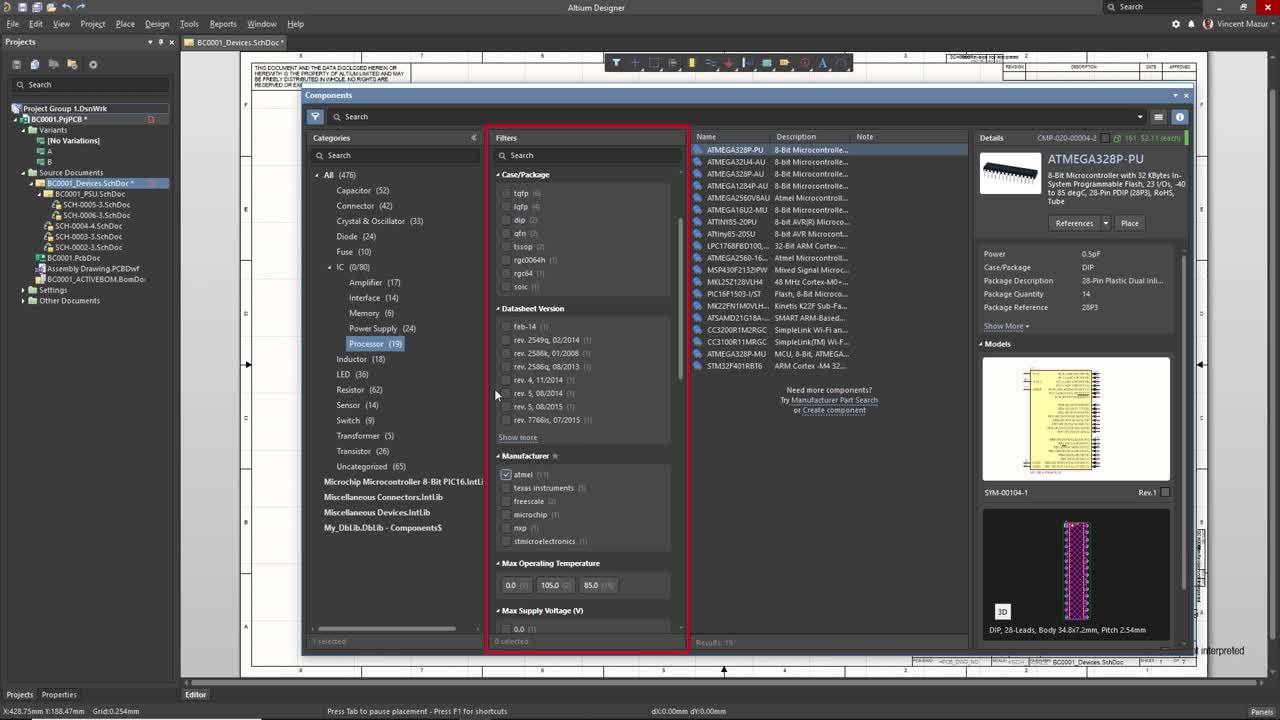

Altium Designer Item Manager Tool

Item Manager Tool

The Item Manager, is a built-in tool that verifies the status of all the components in a PCB design. It first identifies the source for each component looking to see what Library they came from. Classifies each component into 2-categories either managed or unmanaged. Now with Altium Designer® 19 the Components Panel has become more advanced.

See how How to use libraries in Altium Designer 19

Which really helps to tell which components are from a controlled source or from that dreaded and pesky…. “Rogue Library”.

Furthermore, through the Item Manager, it shows the Component Status meaning if a component has been updated in your library it shows that component in your design as “Out of Date”. Clearly showing that it should be updated to sync it back up to the component in the library.

The final information that the Item Manager provides is the life cycle for each component. So, it easily flags those items that may be in a “New” state which as we know now means a component has not been reviewed and verified.

Through this one tool we can fully make sure that our design has a singularity of sources.

Nexus PCB Data Management

The primary purpose of Nexus is as a PCB Data Management System. Originally it started under the name of the Vault just as a component Library tool. But, it developed from there very quickly expanding into a tool which would allow the setup, storage and managing of any size PCB Database. Now it supports everything involved in the process can be stored and managed in Nexus. Including reusable design blocks and entire PCB designs. Becoming it’s own built in Part Lifecycle Management (PLM).

Nexus Design Flow Process

As mentioned before, Nexus took a huge deviation out of the PCB design area and made a grand entrance into the Project management area. With my experience with Rogue Libraries, and after starting our brand-new single library in the Nexus System. The other side of that problem was that we needed to get control of our process’. Get everyone pointed in the right direction.

Nexus forced us to evaluate our process’ and to ask those major questions of all Projects:

#1 What were we doing?

#2 Why were we doing it?

#3 How were going to do it?

#4 When were we going to do it?

With a simple design process flow chart format, it was very easy to start and setup. Also, within the addition of any forms, information instructions could be embedded inside it. This allowed us to conduct designated Design Reviews with specific requirements. All those forms and checklist being embedded into the flowchart. This was a true game changer for us.

With the singularity of the library now we had singularity of the process.

Pillar #2 M - Managed Pillar

With a simple design process flow chart format, it was very easy to start and setup. Also, within the addition of any forms, information instructions could be embedded inside it. This allowed us to conduct designated Design Reviews with specific requirements. All those forms and checklist being embedded into the flowchart. This was a true game changer for us.

With the singularity of the library now we had singularity of the process.

Roles

Each user of the system should be identified and their role in the process. This becomes very vital as the process is worked through, those individuals will have required responsibilities. Which should be documented on what is expected. Bear in mind, that you must first identify how a certain role fits into the process.

Permissions

This really becomes a set pattern at this point. Data inputted, combined with each individual role, with a desired output. What will that individual be required to do with that data? Gives some really needed controls to the whole process. Allowing only certain people to change the data. This will be vital to assure the integrity of the information is maintained.

Revisioning

To assure that each item in a PCB data system is truly managed, there must be both a revisioning and lifecycle. Each item will have a new revision level when any changes occur.

That revisioning scheme can either be a standard template or custom-made to adjust to any company system or standard. Than easily cycled through. But in addition, many times overlooked concern is the keeping the history of those changes. Nexus allows for the documented notes. This is a tremendous help when you are trying to go back and determine not just what was done but why.

Lifecycle

The other side of the coin is the lifecycle. Nexus once again is completely adaptable to whatever lifecycle scheme is needed. This includes from the very moment when the Electronic Engineer first begins to develop a concept all the way through to a finished design and beyond.

It is very important to set these Revioning and lifecycle schemes up before they are used. Simply because it is very difficult to change in mid-stream. Multiple schemes should be setup for various items. For example, in our specific situation we had other items in our Nexus and training materials. For those additional items they would not use either the same revisioning nor lifecycle scheme as a component would. So, we were able to add on any scheme that was needed.

What is a really great feature of Nexus is the ability to combine a certain revisioning scheme and a lifecycle. When certain levels of the lifecycle are reached automatically the revision scheme is implemented. Exactly what we are looking for absolute and complete management of the data.

Pillar #3 A - Architecture

With a very easy to use folder setup configurations, it is very easy to setup any architecture needed. Keeping in mind that having separate folders for the component information parameters and the component models of the symbol, footprint, 3D model, etc.

It is important to plan out what your architecture will be. You can easily add to it, but it becomes difficult when you try to move or rename entire directories. A good start is to set up your part categories and begin to add your families as you see that they are needed.

Pillar #4 R - Reviewable

As mentioned before, a very vital area is to assure the quality of the data stored. Fortunately, whenever any changes are made on any part of a component or it’s models, Nexus automatically reverts the life cycle back to a “new” state. This indicates such changes have happened.

Component Review Process

To assure the integrity of the PCB Design is maintained it is very important not to use those modified components until they have gone through a Review Process to assure they are correct. A common policy is that no PCB Design can be released with those “New” components. They must be reviewed and “Released”. That is done through a Component Review Process and Audit Team that sit down with the component information and the datasheet to see if they match. The verification needs to be driven by the Datasheet. Just to get another set of eyes inspecting always helps.

Nexus has several fantastic tools available to help in this design Review process.

Component Design Rules DRC Checks

Component Rule Check

Just like a normal Design Rule Check for a PCB Design, Nexus has a rather detailed Design Rule Check for the component level. This has been a great improvement from the past when things had to be visually inspected. One hoped that nothing was missed. Now simply setup the DRC rules and run them, this comes back with a full report.

Compare Components

Component Compare tools

It is always a good step to compare one version of a component to what was previous. Sometime unintentionally things are sometime moved, or things happen. Nexus allows for the comparison of any component revision to another to see very clearly if some unintended change occurred.

Nexus and the Component

As we saw in chapter four, that all electronic components used in PCB design are made up of several items including the parameters, circuit simulations and sourcing. Nexus completely allows the organization of all the required information and models used.

Above that, with Nexus and their partnership with Octopart® has allowed them to revolutionize how Components are created and stored in the PCB Data System. It used to be with each new part that required item would need to be either brought in or created. ALl the Component information (Parameters) would be copied and pasted in. With the Nexus system now, the only step is to enter a component part number and with that it searches for the component and automatically brings in the component parameters, the schematic symbol, the Footprint with its 3D model the sourcing and let’s not forget the datasheet.

Then to make it even easier for us that information is automatically linked to the source meaning that whenever any changes happen, then it is automatically updated.

Automatic Component Parameters

My only response to that is … WOW. I keep trying to let Altium know that many of the people who work in the PCB industry work by the hours and because of these new innovative tools they are forcing us to come up with new excuses why things take so long.

This has saved a tremendous amount of time but also it has now increased the integrity of the components used. As I mentioned before where your pipeline is hooked up to, now we can directly connect to the component source and keep it connected.

- Component

- Models

- Parameters

- Sourcing Part choices.

Pillar #5 T - Tailored

The only other point that I would add that has not already been addressed is that throughout Altium and Nexus, is that the ability to document the history of the process is very well organized. With the ability to add the notes of changes on components, designs or having any verification or validation notes. These are searchable to be able at any point to see where problems arose than to fix them.

When you see this whole design cycle as not a straight line but rather as a circle which feeds back onto itself to verify and improve the data. This is where the PCB Data Management area becomes a very powerful tool for everyone involved in the process.

Conclusion

I trust that we now all have a better understanding of this area of PCB Data Management. Of course, we have only scratched the surface of this rather detailed subject. There is a huge need for PCB Data management with the ever-shifting paradigm of our entire industry. More than ever before we need to be proactive regarding those changes and be prepared by putting into place mechanisms to be the leader in the industry. With that state of constant change, I hope you take that as a rallying call not be disheartened or discouraged but rather as a challenge. A challenge to learn and study this special field of electronics.

Now that we have seen the structure of a PCB Data Management System by looking at the S.M.A.R.T. rule, the details and specifics, the various roles involved, the PCB Data distribution throughout the design process and lastly the tools that can be used to set this all up and run it. Only one piece is still missing.… YOU. Which is by far the most important and the most exciting. Because I know that you are a type of person that strives for excellence. With this new knowledge and the know-how, combined with the tools available with a smidgeon of your ingenuity…… the sky is the limit.

I mentioned early on in this document regarding the quote from Creighton Abrams of “How do you eat an Elephant? One bite at a time. Always remember that. Now that we have taken this journey through this fantastic subject of PCB Data Management. We can now see that this really is a never-ending process. The further you go down the road the more that we see that there really is no finish line. That there is no end. To continue the analogy, with each bite of the Elephant it continues to grow. So, what should we focus on? It is not what is still “Left” but rather what has been “Done”. Knowing that with what you hold in your hand, you will put it to good use and take the next step forward and actually “Do it”. It was once said “the smallest steps taken in the right direction is sometimes the biggest step of the journey. Tip Toe if you must but TAKE THE STEP. I hope as we walked through subject that it has spurred something inside that has given you the direction that was needed for you to determine next steps you need to do. Because really this knowledge is totally useless until it is put into practice and actually done. Understand you are not in this alone that there are leaders throughout this entire industry are completely willing to help and offer suggestions.

The story is told of one of the early missions of the Space Shuttle where they took a hive of bees to see what the effects of weightlessness would have on them. The first day the bees flew around as normal, but the second day they began to realize that that they didn’t have to fly since they were floating everywhere. Couple days later all the bees had died. The only explanation that the biologist could give is that the bees were designed with a purpose to fly. When they weren’t fulfilling their purpose, they died.

What is our purpose as a PCB designer or engineer in this industry? Is it just to fill a cubicle or is there something more to all of this? I hope that your answer to answer is “YES there is”. I would also hope that you would know that purpose. I would add that. Above understanding your purpose, is to have a passion for this thing called Printed Circuit Design. For many this is not a career, but rather an absolute passion, that burns deep down inside of them. When you combine that purpose with a passion, then and only then will you see and realize your potential.

As being a devoted fan of Star Trek, I recall that famous line from Star Trek VI: The Undiscovered Country at the ending scene, as Captain Kirk is asked “the Course Heading Captain….” Captain Kirk thinks for a moment and replies. “Second Star to the Right and straight on till morning”. What does the future hold for our industry? Really not sure, but I do know that no matter what challenges and changes may occur, that we will face it as the talented people we are. That have taken up this profession and will face whatever we need to with a resolve, innovation and determination. Forging a constant path forward.

As a PCB Designer …. You are the Builder of Dreams. Realize your electronic designs with Altium, click to try the flagship product Altium Designer anytime and see how easy it is.

Learn more about Electronics Part Shortages and listen to the OnTrack Podcast with Judy Warner and guest John Watson. Watch the whole episode here: